ISO CLEANLINESS CODE FOR HYDRAULIC FLUID CONTAMINATION

As part of our program to continually evaluate industry standards to ensure the most accurate analysis for our customers we will now use the ISO 4406 (2017) 3 digit code standard for particle counting. Reporting at ≥4µ, ≥6µ and ≥14µ as opposed to the two digit code method of ≥5µ and ≥15µ. We will cease reporting to NAS1638 for all Marine applications. Please see below a comprehensive explanation of the ISO 4406 method. If you have any questions do not hesitate to contact us at enquiries@spectro-oil.com.

The ISO 4406 Method

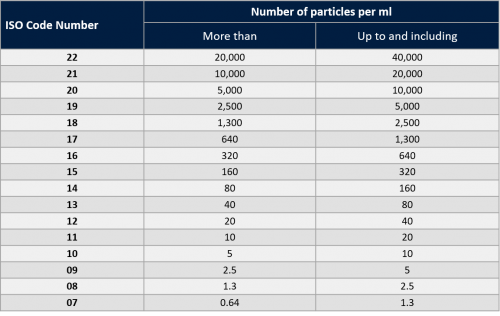

The concept of particle counting can be confusing as it is not an actual precise count. It is described by a number of particles related to the factor of 2. For example, if there was a count of 512 particles in a 100 ml sample of fluid that would be 2 x 2 x 2 x 2 x 2 x 2 x 2 x 2 x 2 or 29 i.e. 512 number of particles and we would record the number 9 as the count. That in itself does not mean there were 512 particles counted – it actually means that the number of particles was between 28 (i.e. 256) and 29 (i.e. 512). This is further complicated as what is actually reported is the maximum contamination level to be found in only 1 ml (i.e. 1/100th) of the sample not 100 ml. Reverting to the figure the 9 count means we are to expect between 2.5 and 5 counted particles in every 1 ml of sample fluid. See table below.

Worked example: 17/13/9 (remember each number set is 4µ, 6µ and 14µ respectively)

This gives us two pieces of information; both the size and the quantity of the particles.

The first number gives us the range of particles in the 4µ or larger range in 1 ml of sample.

The second number gives us the range of particles in the 6µ or larger range in 1 ml of sample.

The third number gives us the range of particles in the 14µ or larger range in 1 ml of sample.

Note that the number stated is the power to which 2 is multiplied. The result is then divided by 100 and rounded to give the maximum number of particles of a certain size or larger that can be expected in a 1 ml fluid sample. The ‘actual’ particle count would be somewhere between ½ of that number and the number.

Worked example:

The ≥14µ or larger particle count is represented by 9 - this equates to the number of particles at that size somewhere between 28 29 divided by 100 (remember the 256 and 512). This gives us rounded up figures of 2.5 and 5. Thus the number of particles in 1 ml of fluid ≥14µ or over is anywhere between 2.5 and 5.

Sampling over a precise time period and trending is vital as the difference between a 17/13/9 report and a 18/13/9 report could be 1 particle or it could be 1200. There are set ‘typical’ cleanliness codes for hydraulic machinery and manufacturers recommendations should be adhered to as different components have different tolerances for contamination.